Let’s say if you are not professional and you decided to buy a used excavator no matter because of a low budget or short work cycle, apart from reviewing the seller’s ratings you still need to look at some simple but determining factors in the quality of the parts or equipment that you acquire, they certainly do influence if your money worthy of paying. And those factors are including their operating hours, fluids conditions, maintenance records, signs of wear and engine exhaustion.

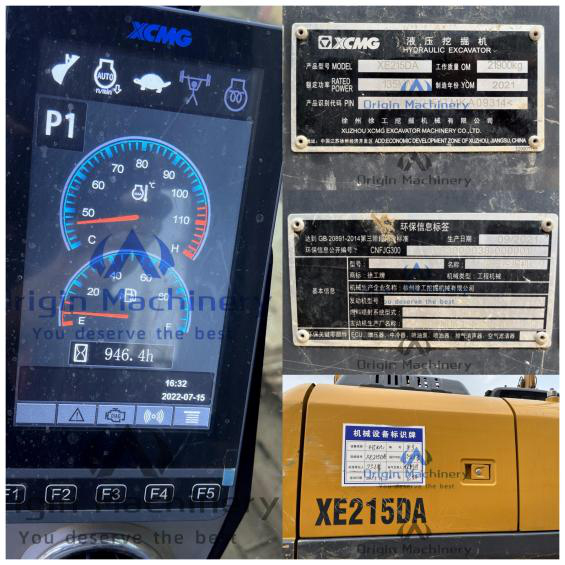

1. Operating hours

How many hours a machine has operated for isn’t the only factor you should consider when evaluating a machine’s condition but, as with looking at miles when shopping for a used car, it’s a good place to start.

A diesel-engine machine can last into 10,000 operating hours. If you think it may be pushing the upper limits of hours then you may want to do a quick cost/benefit calculation. This will help you to determine if the money you’re saving on an older machine is going to be worth the additional maintenance cost of taking care of something that may break down more often.

Keep in mind that regular maintenance is still important. A machine with 1,000 operating hours that hasn’t been well-maintained may be a worse buy than a machine with more hours.

2. Check the fluids

Fluids to look at include engine oil, transmission fluid, coolant, hydraulic fluid, and more.

Looking at a machine’s fluids will give you insight into not only the current condition of the machine, but also how well it’s been maintained over time. Low or dirty fluids could be a warning flag that the previous owner hasn’t kept up with a regular maintenance schedule while clues like water in the engine oil could be a sign of a much bigger problem.

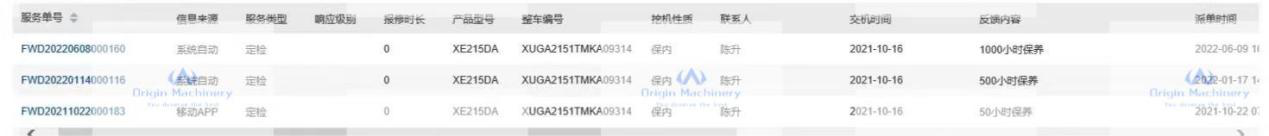

3. Maintenance records

The most sure-fire way to know if a machine has been maintained at regular intervals is by looking at its maintenance records.

How often were fluids changed? How often were small repairs needed? Has anything gone seriously wrong with the machine in its operating life? Look for clues that could indicate how the machine has been used as well as how it’s been taken care of.

Note: records don’t always make their way from each owner to the next so an absence of records shouldn’t necessarily be taken to mean that maintenance hasn’t been done.

4. Signs of wear

Any used machine is always going to have some signs of wear so there’s nothing wrong with dings and scratches.

Things to look for here are hairline cracks, rust, or damage that may lead to problems in the future or reveal an accident in the machine’s past. Any repairs you’ll need to do down the road will mean added costs and downtime where you can’t use your machine.

Tires, or undercarriage on tracked vehicles, are another good place to look. Keep in mind that both are expensive to replace or repair and can give you a lot of insight into how a machine has been used.

5. Engine exhaustion

There’s no better way to evaluate an engine than to turn it on and run it. How the machine runs when the engine is cold will tell you a lot about how well it’s been maintained.

Another tell-tale clue is the color of the exhaust smoke the engine produces. This can often reveal issues that you didn’t know existed.

- For example: black smoke typically means the air/fuel mixture is too rich in fuel. This could be caused by a number of issues including faulty injectors or something as simple as a dirty air filter.

- White smoke could mean that fuel is burning incorrectly. The engine could have a faulty headgasket that lets water mix with the fuel, or there could be a compression issue.

- Blue smoke means the engine is burning oil. This is likely caused by a worn ring or seal but could also be something as simple as an over-fill of engine oil.

Contact sales@originmachinery.com ask for special price and more used excavator videos.

Post time: Aug-03-2022